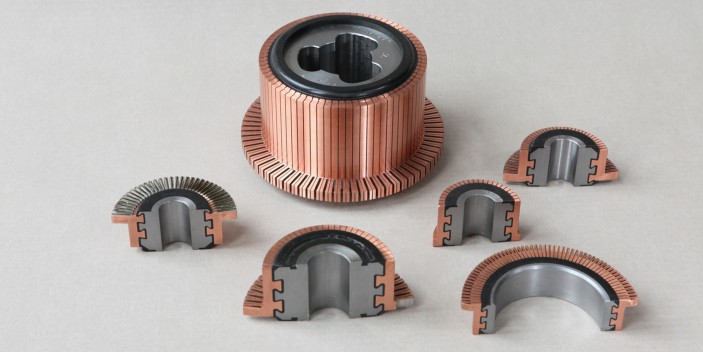

Moulded commutators SUKaT Ø 60–400 mm, peripheral velocity of 60-80 m/sec, heat classes F and H, with permanency of form. May be used f.e. for engines of material trucks operatting under high mechanical and thermal stress ( fork-lift trucks, traction ).

CATALOGUE

Commutator catalogue download.

INQUIRY

Fill out inquiry form.

Solution

The internal construction differs from common constructions of moulded commutators. The anchorage of segments in the cyrrying sleeve with the use of dovetails with definitively given outer form and position of the segment in resulting in the construction featuring a high radial stiffness and ensuring considerable mechanical stability of the commutator segment ring. A relatively thin layer of pressing material enables a very good heat transfer between the segment ring and the commutator sleeve.

Advantages of SUKaT

- High permanency of form at extremely high peripheral velocity and elevated temperature

- Big cross section for cooling ducts in the commutator sleeve independent of the commutator length

- High efficiency of motor cooling

- High dimensional and form accuracy

- Insulation class F, on special reguest class H

Technical data

- Segment copper: CuAg 0,03 % or 0,1 % or as requested

- Segment insulation: built-up mica, remica or as requested

- Commutator sleeve: steel, either with air events of different execution or without the air vents

- Diameter range: 60–400 mm

- Axial length of the commutator segment: 25 – 250 mm

- The commutator is available with or without lugs, with cut-through grooves for conductors tinned or without tinning, or without the grooves

Commutators may be produced in large and smaller quantities or even as piece goods at low costs of manufacture preparation and short time of delivery.

Miroslava Gammonová

+420 771 277 445

gammonova@cebes.eu